Companies are turning to innovative condition monitoring and predictive maintenance solutions to maximize the performance of their machines. For rotating machinery, this is made possible by energy efficient and robust wireless sensors.

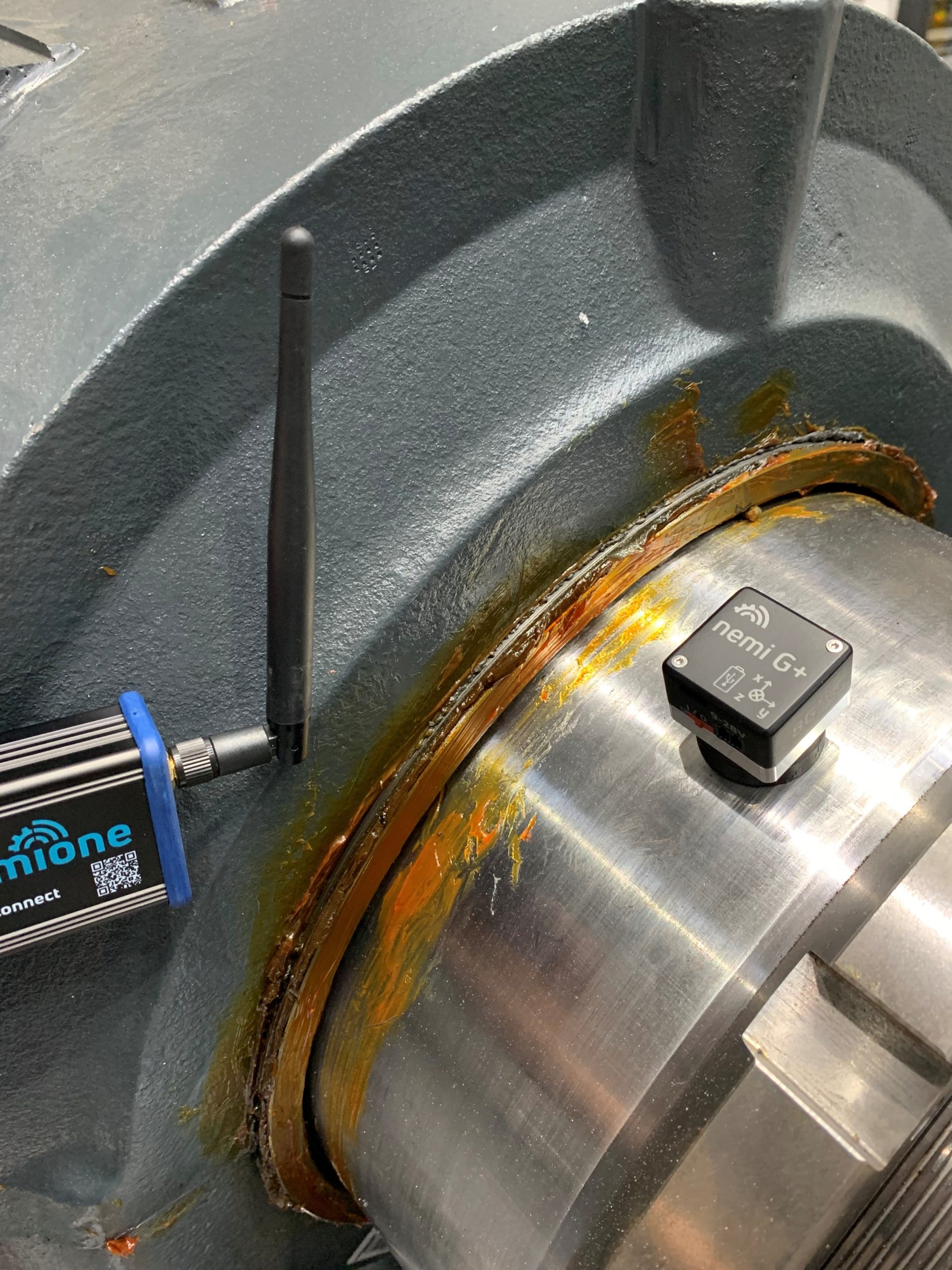

To monitor the performance and condition of machines in real time, nemione sensors are easily and flexibly mounted on the machine by gluing, screwing or magnetically. While the machine is in operation, the wireless sensors simply rotate along with it without the risk of cables getting caught. The direct coupling of the sensor to the damage-relevant parts in the rotating system enables better detection accuracy in the event of machine faults.

A wide range of data such as vibrations, forces, temperatures, pressures and other physical variables can be recorded and transmitted wirelessly in real time via nemi Link radio technology to a central data acquisition system, nemi EgeBase. The data acquisition system can automatically analyze the data and provide an overview of the machine’s performance and any deviations from normal values. By capturing the angle of rotation, optimal data quality is achieved using angular resampling methods.

👉 Your advantages:

nemione sensors provide you with reliable, efficient condition monitoring even on rotating components. Accurate data collection, real-time monitoring, wireless connectivity and easy installation enables you to optimize operations and increase productivity while controlling costs.

You need substantial data from your (rotating) machines or assets? Whether logging and analyzing process and condition data, predictive maintenance or digital twin: With our wireless sensors and intelligent data analysis, you will reach your goal.

Efficient Wireless Condition Monitoring: Maximizing Performance of Rotating Machines 💪

In