For condition monitoring of machines or entire plants, the used sensors

1. require energy and

2. must provide the data.

Both can be done via power or data cables. But does this make sense?

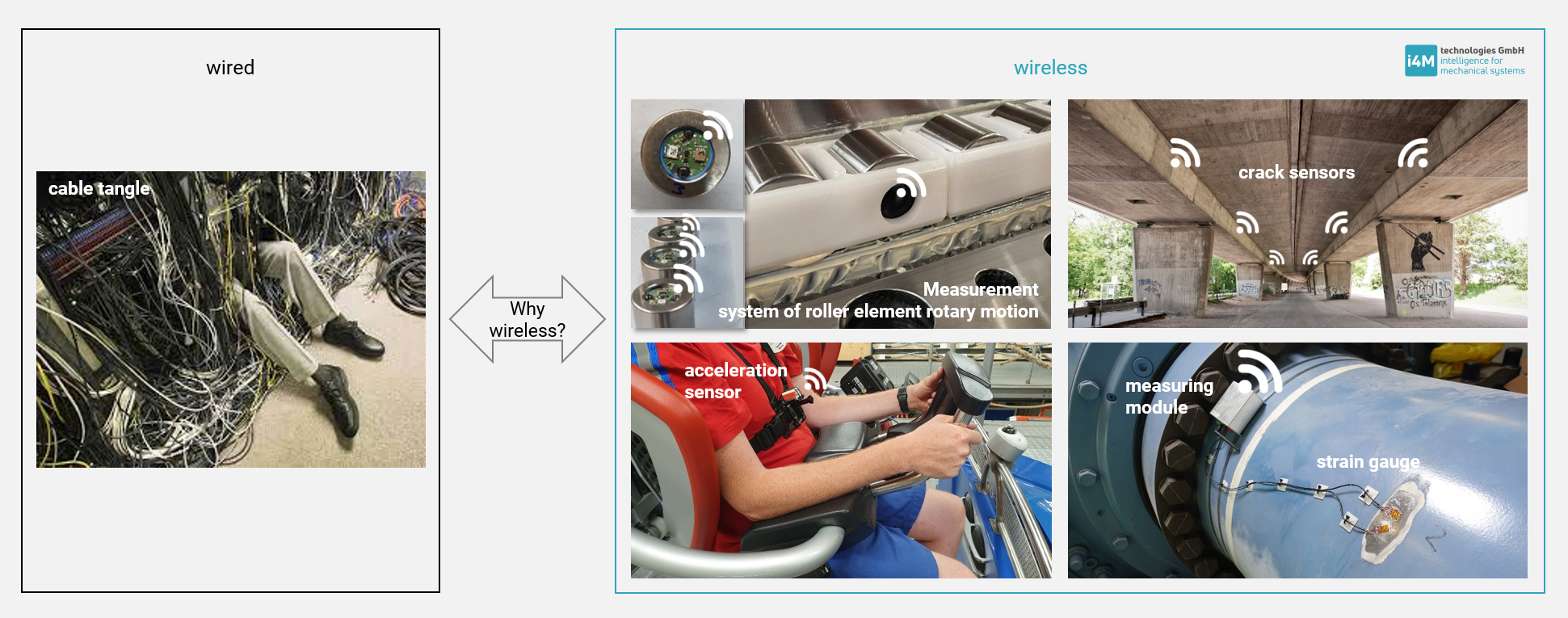

The greater the distance between the measuring point and the PC, the longer the cables have to be. The more complex the measuring point, the more cables are needed. It gets even more complicated with moving or rotating components. The cable itself is not expensive, but it is certainly the employees who often spend hours, days or weeks laying the cables and keeping them apart. And there we have the cable tangle!

For this reason, we rely on wireless data transmission via radio / 4G and battery-powered products whenever possible. Our mission is to obtain meaningful data even in demanding applications.

Even though we are often confronted with challenging situations, our highly efficient and energy-saving wireless technology nemi Link allows us to achieve long battery runtimes of our wireless sensors. With energy harvesting or solar panels, these runtimes can be extended even further.

Why wireless: Because a mains power supply is not always possible and because wiring long bridges is very complex.

-> Better: We have equipped long bridges with up to 30 battery-powered wireless sensors. We made possible 7 years of runtime completely without mains power.

Why wireless: Because wiring of moving or rotating components is difficult or often impossible.

-> Better: We used our wireless sensors on moving or rotating components in various applications: on pitch bearings of wind turbines, on gearboxes, on chain links, on roller coasters or integrated in roller elements. Our sensors simply rotate/move along without cables getting caught and provide reliable data.

You want to know more? Feel free to contact us!